block direct sunlight from reaching the cold water basin and fill media, while also preventing debris from entering the tower. This helps inhibit algae growth and scale formation.

Constructed from UV- and corrosion-resistant PVC, these louvers are CTI-certified and designed for easy installation, inspection, and replacement—reducing maintenance costs and extending the service life of the cooling tower.

Compass Series

3.Custom Features

Date : 2016-10-30 15:05| >Structural Material |

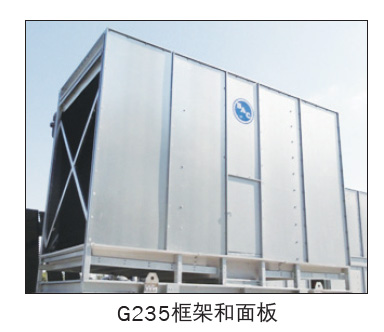

| BAC utilizes G235 galvanized steel for the structure and panels, ensuring extended service life of the cooling tower. The equipment features a reinforced frame structure with superior strength, designed to meet a seismic design rating of SDS 1.3g and a wind load rating of 66 psf. |

|

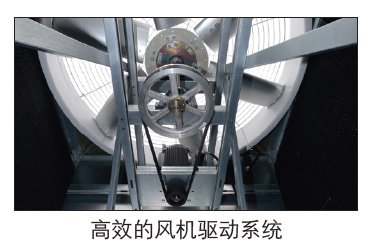

| Drive System |

| The fan drive system delivers the necessary airflow to expel heat into the atmosphere. All BAC drive systems are equipped with high-efficiency motors specifically designed for the hot and humid operating conditions of cooling towers. These motors feature permanently lubricated bearings, significantly reducing maintenance requirements and costs. |

| >Optional: Vibration Cutout Switch |

| BAC offers a mechanical vibration cutout switch to protect equipment from potential damage caused by excessive system vibration. The switch is housed in a NEMA 4-rated enclosure for enhanced durability and protection. |

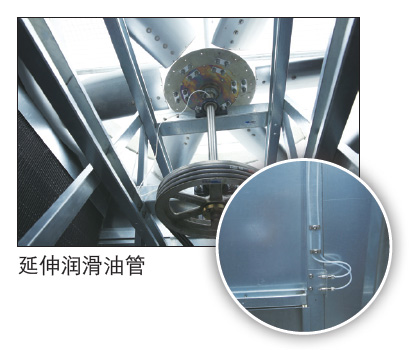

| >Optional: Extended Lubrication Lines |

Extended lubrication lines with grease fittings are used to lubricate the fan shaft bearings. The grease fittings are located inside the fan section near the access door.  |

| >Big cold water basin |

| The cold water basin collects water from both the cooling tower and system piping during shutdown, while also providing the required static head for the circulation pump. BAC’s sloped cold water basin effectively eliminates stagnant water zones during operation, helping to inhibit microbial growth. |

|

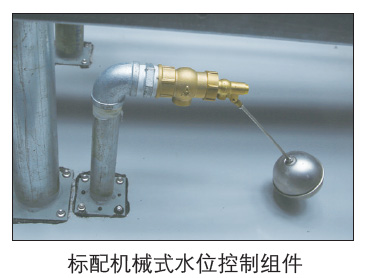

| >标配机械式水位控制组件 |

| 机械式补水阀需要在湿热环境下持续运行。考虑到严苛的运行环境,补水阀运行原理必须简单,而且运行寿命要长。所有BAC 冷却塔设备标配高品质机械式水位控制件,运行可靠,维护简便。 |

|

| >Optional: Side Outlet Sump Tank (Optional)

The recessed side outlet sump tank sits below the cooling tower base, allowing for easier field installation. This option simplifies piping layout and reduces on-site installation time and costs. The outlet is designed with an ASME 150 flat-face flange connection. |

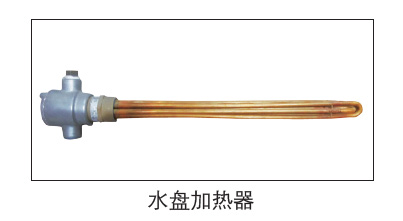

| >Basin Heater(Optional) |

| When the cooling tower is idle for extended periods in subfreezing conditions, freeze protection measures are required. The basin heater maintains water temperature at 4.4°C (40°F), providing a cost-effective and reliable method to protect the cold water basin. |

|

| >Heater Parameters |

|

| >Multiple Unit Installation (Optional) |

| When installing multiple cooling towers in parallel, special measures must be taken to ensure balanced water levels in each cold water basin. Without proper water level balancing, one unit may overflow while another continues to receive make-up water, resulting in unnecessary water waste. |

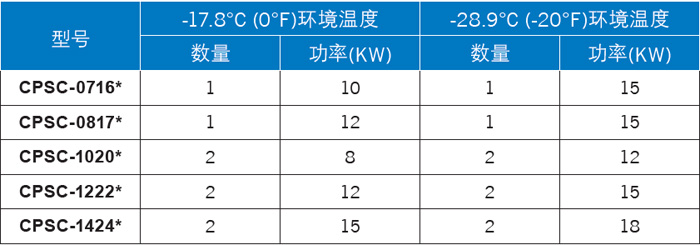

| >Optional: Equalizer Box |

| The cold water basin equalizer box is designed for multi-cell configurations and effectively balances the operating water level across all connected units. |

|

| >Optional: Equalizer Pipe |

| The cold water basin equalizer pipe can be used in place of the equalizer box to balance the operating water levels across multiple connected units. It can also serve as an isolation mechanism between units, allowing for continued system operation during winter or routine maintenance. |

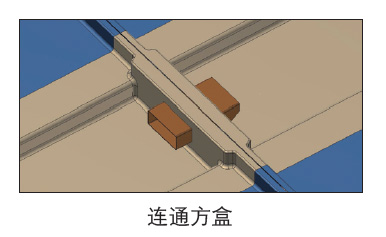

| >Water Distribution System |

| The Compass Series utilizes a low-head gravity water distribution system. Large-diameter, clog-resistant nozzles significantly reduce pump energy consumption compared to pressurized distribution systems. |

| >Fills |

| BAC’s patented HELIX 3i fill is made of PVC and features an integrated design that combines drift eliminators, air inlet louvers, and fill. This optimized configuration delivers excellent thermal performance and water-saving efficiency. |

|

| The optional water distribution system cover prevents debris from entering the hot water basin, ensuring reliable system operation and effectively reducing noise. |

|

|

| The Compass Series cooling towers offer two factory shipping options to meet diverse customer requirements. |

|

|

| >Easy Installation |

| Knockdown shipment is suitable for various site conditions, offering lower transportation costs and simplified installation. All components and assembled units meet the same thermal performance standards as factory-assembled units. |

| >Optional: Factory-Assembled Shipment |

| BAC units can be fully assembled at the factory and shipped to the job site, ensuring product quality while minimizing on-site installation work. During the design phase, BAC takes measures to reduce the tools and time required for lifting and rigging. |

| >Rigging Guidance |

| Follow the lifting guidelines provided to reduce installation time—especially important for multi-cell installations. |

|

| >Low Sound Options |

| Noise control has become an increasingly important design criterion in cooling tower projects. BAC offers a wide range of sound-reduction options to meet various acoustic requirements and provide cost-effective, low-noise cooling solutions. |

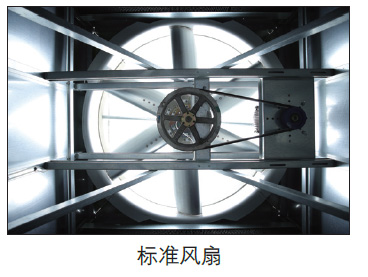

| >Standard Fans |

| All Compass Series cooling towers are equipped with fans optimized for low-noise operation without compromising thermal performance. |

| >Low Sound Fans |

| Optional quiet fan configurations can reduce noise by up to 9 dB. Fans with steep blade angles operate at lower speeds to achieve significant sound attenuation. BAC cooling towers equipped with quiet fans are CTI-certified for thermal performance. |

|

| >Inlet options |

| During operation, airborne debris can be drawn into the cooling tower along with the intake air, contaminating the circulating water. The Compass Series offers optional CIS that prevent debris from entering the system without restricting airflow. This helps reduce maintenance requirements and ensures consistent thermal performance. |

| >Combined Inlet Shields(Optional) |

|

|