| >100% Thermal Performance |

>All Compass series products are CTI-certified, ensuring 100% compliance with thermal performance requirements.

|

>Certified through CTI’s rigorous testing program and annual random inspections, guaranteeing that every unit meets its design thermal performance

|

|

| >Reliable Operation |

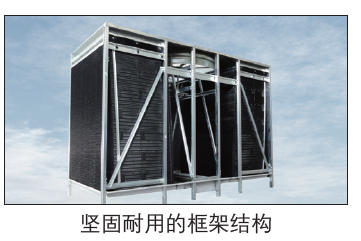

| >G235 galvanized steel frame and panels withstand up to Category 12 winds and seismic level 8 |

>Unique waterproof bearing design tailored for cooling tower environments

|

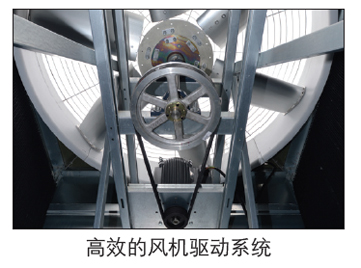

| >Aluminum alloy fan blades offer longer lifespan and greater reliability than conventional FRP fans |

| >Rust-resistant aluminum alloy sheaves reduce belt wear |

| >Motors specifically designed for cooling tower duty ensure reliable drive system operation |

>Optional water distribution covers prevent debris entry into the hot water basin, protecting system integrity

|

>Cold water basin features minimal seams with steel support beneath each seam to minimize leakage risks

|

| >Extra-large cold water basin with anti-vortex outlet screen prevents pump cavitation and ensures system safety |

|

|

| >Easy Maintenance |

>Direct internal access for crossflow tower maintenance

|

>Split bearing design allows for easy lubrication and replacement

|

>Lightweight aluminum alloy sheaves with taper-lock bushings for easy installation and removal

|

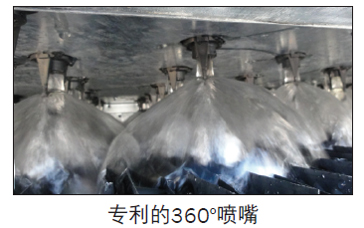

>Twist-lock spray nozzles are easy to remove, reusable, and maintenance-friendly

|

>Sloped cold water basin eliminates stagnant zones, inhibiting microbial growth

|

>Fill suspended above sloped basin allows dirt and debris to be easily flushed away

|

>Optional hot water basin covers support up to 90.7kg of concentrated load, facilitating equipment access

|

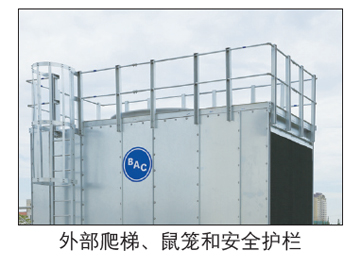

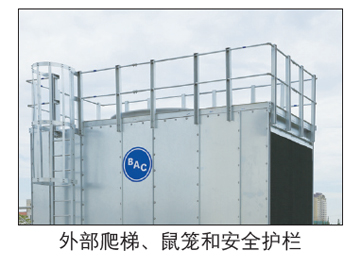

>External ladders, safety cages, and railings allow safe access to the water distribution system

|

>Big access doors and internal walkways enable easy entry and maintenance within the tower

|

|

| >Easy Installation |

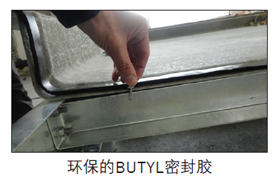

| >Cold water basin features minimal seams and uses environmentally friendly BUTYL sealant, eliminating the need for on-site fiberglass hand-layup and saving installation time |

| >All models can be directly installed on parallel steel beams through the side panels for simplified setup |

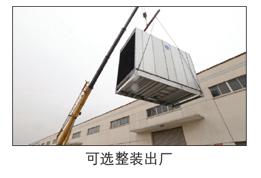

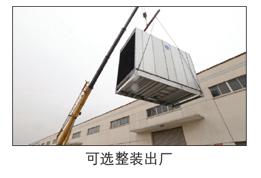

| >Optional factory-assembled units ensure installation quality and significantly reduce on-site labor |

|