Evaporative condensers provide heat rejection for many types of systems, and the specific application will largely determine which BAC Evaporative Condenser is best suited for a project. The information contained within this section is geared towards the use of evaporative condensers in the HVAC and light industrial markets only. Evaporative condensers are used in these markets to provide lower condensing temperatures and compressor horsepower savings of up to 15 percent when compared with traditional systems. For technical support with a refrigeration application, contact your local BAC Refrigeration Sales Representative.

|

|

Principle of Operation

|

|

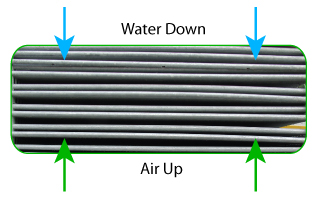

The vapor to be condensed is circulated through a condensing coil, which is continually wetted on the outside by a recirculating water system.Air is simultaneously blown upward over the coil, causing a small portion of the recirculated water to evaporate. This evaporation removes heat from the coil, cooling ,and condensing the vapor in the coil.

|

Type |

|

manufactures two types of evaporative condensers: combined flow and counterflow.

|

|

|

|

Water Distribution System

|

| The parallel air and water flows of the CXV allow the spray area to be uncovered(drift eliminators are inside),permitting quick and easy inspection of tile sprays and coils from outside the unit while the CXV is in full operation. |

|

|

Fan Drive System

|

|

The flow of air through most factory assembled evaporative condensers is provided by one or more mechanically driven fans. Axial fan units require approximately half the fan motor horsepower of comparably sized centrifugal fan units, offering significant life-cycle cost savings.

|

|

|

|

Centrifugal Fan:for indoor or restricted outdoor installations and low noise applications.

|

|

|

|

Axial Fan:for low energy consumption on normal unrestricted installations.

|

Reduced Scale Tendency |

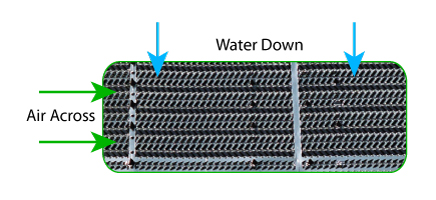

| 1. Air and Water Flow in Parallel Path

Better water coverage around the tubes is due to air and spray water flowing in fl smooth,parallel,downward path over the condensing coil,maintaining full tube coverage.This parallel flow eliminates scale-promoting dry spots since the water is not stripped from tile underside of the tubes by the airflow. |

|

|

| 2.Increased Water Flow over Coil.

The spray water flow rate over the coil is more than twice that of most conventional evaporative condensers.This provides continuous flooding of the primary heat transfer surface for decreased scaling potential.No increase in pump horsepower is required with this higher flow due to the CXV’s unique heat transfer system.

|

| 3.Evaporation Occurs Primarily in Wet Deck

The CXV incorporates combined-flow technology using both primary and secondary heat transfer surfaces.The primary heat transfer surface,the serpentine condensing coil,is the most important as well as the most expensive component in the evaporative condenser.The coil of the CXV is protected from detrimental scale since the CXV coil relies primarily on sensible heat transfer and therefore is less susceptible to scale formation than are other designs that rely primarily on 1atent (evaporative)heat transfer from the coil surface.

|

| 4.Colder Spray Water

Spray water at colder temperatures has a lower propensity to form scale because scaling compounds remain in solution rather than depositing as solids on the coil,In the CXV,the spray water over the coil is commonly 4-5℃ colder than other condenser designs due to the addition of the secondary heat transfer surface.The colder spray water alone typically reduces the scaling potential of the CXV by 25% compared to other designs.This is above and beyond the reduction achieved due to the first three facets discussed above. |

|

|

|