Closed Circuit Towers

|

||

| BAC Closed Circuit Cooling Towers provide reliable performance and trouble-free operation for industrial,process,refrigeration and HVAC cooling applications.Heat transfer coil materials and configuration alternatives make BAC Closed Circuit Cooling Towers suitable for cooling a wide range of HVAC and industrial fluids,from water and water-based fluids to hydraulic or quench oils and plating solutions.From the overall design and component configuration to materials and performance specifications.BAC closed circuit cooling towers are engineered to provide many installation,maintenance,and opera,on benefits. | ||

|

Configuration |

||

|

BAC manufactures types of closed circuit cooling towers: combined flow |

||

|

Combined Flow |

||

|

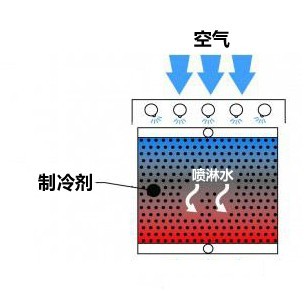

Combined flow is the use of both a heat exchange coil and fill for heat transfer in a closed circuit cooling tower. The addition of fill to the traditional closed circuit cooling tower design reduces evaporation in the coil section, reducing the potential for scaling and fouling. BAC’s combined flow closed circuit cooling towers utilize parallel flow of air and spray water over the coil, and crossflow air/water flow through the fill. |

||

|

||

|

||

|

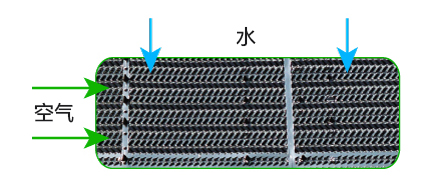

Combined Flow: Crossflow Configuration Over the Fill |

||

|

|

||

|

Fan System |

||

|

The flow of air through most factory assembled closed circuit cooling towers is provided by one mechanically driven fan. The fan can be axial or centrifugal, but the unique advantages of axial flow fan with low energy consumption。 |

||

| Axial fan units require approximately half the fan motor horsepower of comparably sized centrifugal fan units, offering significant lifecycle cost savings. | ||

|

||

|

Axial Fan

|

||

|

Induced Draft |

||

|

Fans can be applied in an induced draft or a forced draft configuration. The rotating air handling components of induced draft equipment are mounted in the top deck of the unit, minimizing the impact of fan noise on near-by neighbors and providing maximum protection from fan icing if units operate in sub-freezing conditions. The use of corrosion resistant materials ensures long life and minimizes maintenance requirements for the air handling components. |

||

|

Capacity Range |

||

|

Product capacities are called out in terms of a flow rate at 95ºF/85ºF/78ºF. This refers to the flow rate of water that the unit can cool from a 95ºF (35.0ºC) entering water temperature to an 85ºF (29.4ºC) leaving water temperature at a 78ºF (25.6ºC) entering wet-bulb temperature. BAC offers selection software to evaluate the performance of a closed circuit cooling tower at any conditions. All capacities shown are for a single cell; multiple cell units can be applied to achieve larger capacities. |

||

| Maximum Entering Water Temperature | ||

|

All BAC Closed Circuit Cooling Towers are capable of withstanding entering fluid temperatures as high as 180ºF (82.2ºC) |

||

| Advantages of Closed Circuit Cooling Towers | ||

|

||

|

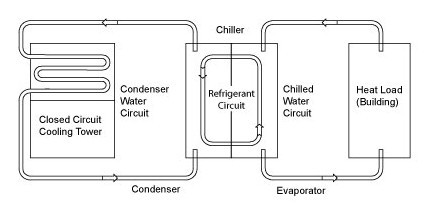

Figure : Chiller Loop with a Closed Circuit Cooling Tower |

||

| Advantages of Closed Circuit Cooling Towers | ||

|

The power production of worldwide chemical、fuel and metal, always discharge waste heat with low quality.please try to imagine there is an ideal discharge heat system which can deal with waste heat like these: |

||

|

Protect the fluid in the industrial process from contamination. |

||

| Protect environments by reduce unnecessary energy wasting | ||

|

Save costs of installation and operation. |

||

| Insure the maximal flow efficiency. | ||

|

|

||

| closed circuit cooling system offer a number of advantages over other heat rejection systems | ||

|

Vs.Air-Cooled Systems:10℃ to 20℃ lower process temperatures,less required space,and lower energy consumption. |

||

| Vs.Once-Through System:Reduces environmental impact,saving up to 95% of the cooling water. | ||

| Vs.Cooling Tower/Heat Exchanger Combination:Closer approach to wet bulb reduced fouling improve process efficiency. | ||

| Vs.Open Cooling Towers:Contaminant free,closed loop cooling significantly reduces process fouling,ensuring constant performance over time. | ||